PRIMARY BREEDING FARMS

HATCHERIES

BROILER FARMS

PROCESSING PLANTS

FEED MILLS

RETAIL

PRIMARY BREEDING FARMS

The poultry supply chain starts with its first link, the primary breeding sector.

Pedigree flocks are raised on farms under very stringent hygiene conditions, disease prevention controls and biosecurity. Over 40 different traits for overall health, welfare and productivity are measured. The selection process only focuses on the genetic characteristics that occur naturally in chickens and are able to be passed on to their offspring.

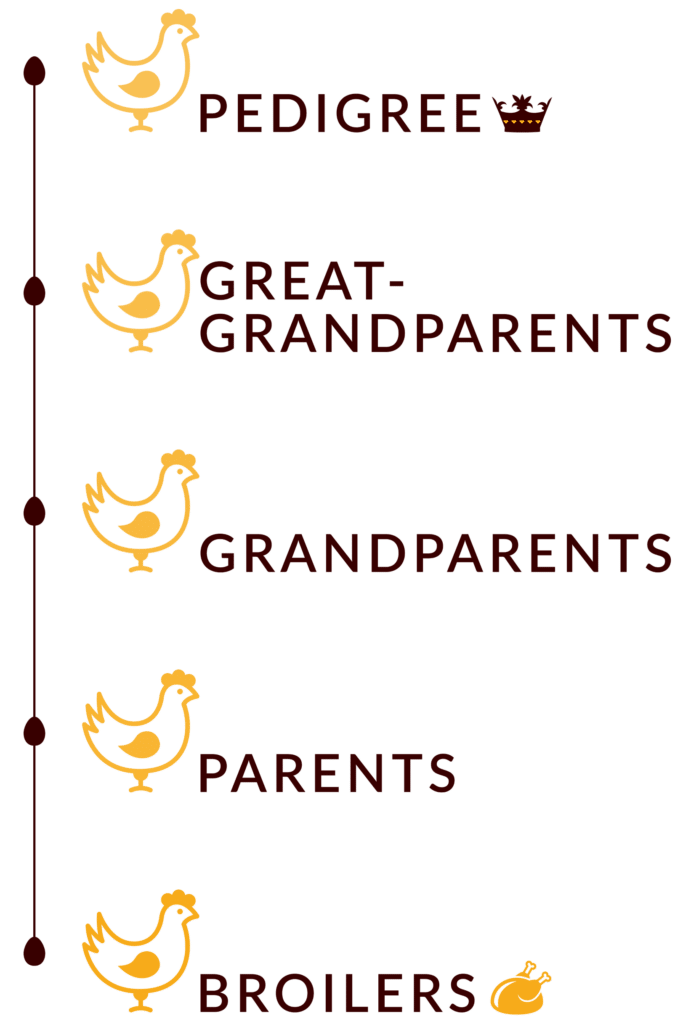

The progeny from the breeding program provides the next generations from great-grandparents (GGP) all the way to broiler chickens reared for meat production.

HATCHERIES

Hatcheries receive fertilized eggs from parent breeder farms and incubate them in a procedure that partly replicates the brooding hen, until the broiler chick is hatched.

Incubation takes about 21 days and is often a two-step process with environmental and hygiene conditions optimized to help the chicks hatch in the best way possible.

On hatch day, all the chicks, females and males, are carefully inspected, spray vaccinated, counted, and placed in chick boxes, ready to be transported at the broiler farm on the same day. Specialized climate-controlled trucks are typically used, depending on climate and transport distance.

BROILER FARMS

Day-old chicks are placed on broiler farms in houses that have been pre-warmed, or under brooding heaters, and provided with water and then feed formulated to meet their nutritional needs.

Most broiler chickens are barn-reared indoors on litter of chopped straw or other bedding materials with freedom to roam the house. Free-range and organic free-range systems where the birds have daytime access to pasture outside the house, are also used depending on the customers’ market requirements.

Broilers are raised following the best welfare, biosecurity, and health conditions, according to best production practices, national and regional laws, and customer requirements.

PROCESSING PLANTS

When birds reach required market weights, they are transported by truck to a processing plant.

Upon arrival, broiler chickens are inspected, and rendered instantaneously and humanely unconscious with scientifically approved methodologies. While unconscious and impervious to pain, they are slaughtered, the carcasses defeathered, and the internal organs are removed. The carcasses are washed, and then chilled, either by a cold air process or by immersion in cold water.

Once chilled the carcasses are graded and weighed, with some going for sale as whole birds of various market weights, some going to be cut up to be sold as chicken cuts or pieces, and some going for further processing into meat preparations or meat products such as cooked ready-meals.